OKAYAMA GIKEN (Minerals) Co., Ltd. is a premier manufacturer of high-quality Caustic Calcined Magnesite (CCM) produced in Dashiqiao Liaoning, China, where is China's largest magnesium ore resource area, with rich magnesite, CCM and DBM (Dead Burned Magnesite ) production is high. Our CCM meets the most stringent European standards and certifications,and recognized for their outstanding purity and reliability, making them suitable for a wide array of industrial applications. With a solid reputation in both European and American markets.

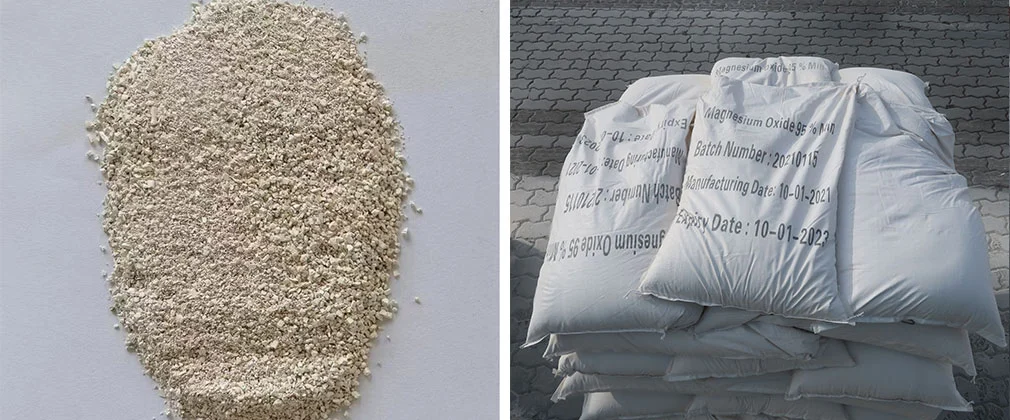

Caustic Calcined Magnesite is also known as Activated Magnesium Oxide, Caustic Magnesia or CCM, which is a magnesium oxide (MgO) product made from magnesite (MgCO₃) or other magnesium-containing compounds by low-temperature calcination at 800-1100°C. Due to the low calcination temperature, CCM has high activity and large specific surface area, and has the characteristics of chemical stability, environmental remediation and fire resistance, and is suitable for various industries.CCM is mainly used in smelting material, refractory and moisturizing,rubber industry , agricultural applications, hydrometallurgical processes, pulp and paper, construction and cement, chemical and pharmaceutical industries, environmental applications, glass industry.

High activity: CCM is highly reactive and suitable for various chemical and industrial uses.

Light specific gravity: Compared with fused magnesium (FM) or sintered magnesium (DBM), it has a lower density.

Chemical properties: It can react quickly with water and acid to produce magnesium hydroxide or magnesium salts.

Adjustable purity: Depending on the raw materials and production process, CCM can provide different contents of MgO (usually between 65% and 95%).

Refractory industry: refractory bricks· refractory castables·steel·glass·cement

In high-temperature environments, CCM's refractoriness, thermal stability, low expansion, corrosion resistance, and high-temperature chemical activity make it an important raw material for industries such as refractory materials, steel smelting, glass manufacturing, and cement production. MgO has a high melting point (2800°C). CCM can effectively resist the corrosion of molten steel and slag on the furnace lining, improve steelmaking efficiency, and can be used for refractory repair and hot spraying of high-temperature melting furnaces to reduce production costs; it can react with sulfur (S) in high-temperature operations to reduce SO₂ emissions in steel plant flue gas, meeting environmental protection requirements. As a magnesium binder, CCM is mainly used in glass production for glass formula modification, refractory lining materials, glass melting furnace repair, etc.; CCM is mainly used in the cement industry for refractory materials, alkalinity adjustment, magnesium cement additives, etc. It can adjust alkalinity in the cement production process, reduce the impact of harmful elements, optimize cement clinker quality, reduce kiln crusting, improve fluidity, and increase production efficiency. It is suitable for high-strength concrete applications.

Agriculture: Animal Nutrition · Fertilizer · Agriculture

Caustic Calcined Magnesite is used as a soil conditioner to adjust the pH of acidic soils and increase crop yields. As an animal feed additive, it supplements magnesium.

The main source of magnesium is milk and dairy products. But due to the lack of magnesium content in soil and plants, animals often suffer from insufficient magnesium intake, which ultimately leads to low magnesium content in dairy products. In order to solve these problems and prevent magnesium deficiency, especially in lactating and grazing cattle and sheep, it is necessary to add some additional magnesium to their daily feed. Caustic Calcined Magnesia is used in compound feeds and premixed with other necessities as animal and cattle feed. In addition, fine magnesium oxide powder can be sprinkled on the fields or mixed into the drinking water of animals in the recommended proportions.

Environmentally friendly environment: · Soil purification · Waste neutralization · Water treatment · Flue gas treatment

Alkaline calcined magnesite powder for water treatment acts as a precipitant in the water treatment process to remove heavy metal ions and can effectively remove phosphorus. When MgO is applied to wastewater, it reacts with the solution and becomes magnesium hydroxide (MgOH)2, which does not produce harmful byproducts, so it has minimal impact on the environment. Alkaline calcined magnesite powder is an excellent water softener because it can remove minerals that cause water hardness and prevent scale accumulation in pipes and appliances; its high alkalinity helps neutralize acidic substances and balance the pH of water. It also helps remove impurities and pollutants by binding them together to form clumps that are easy to remove. In addition, another significant advantage of alkaline calcined magnesite powder for water treatment is its ability to act as a disinfectant, which can kill bacteria, viruses and other microorganisms that may cause waterborne diseases, ensuring healthy water quality.

Industrial use: Papermaking, rubber, and plastics industries

Caustic Calcined Magnesia is used as a flue gas desulfurizer to reduce pollutants emitted by industries. Caustic Calcined Magnesia is highly active and can react quickly with acid. Its high purity helps ensure the quality of chemical products. In the papermaking, rubber, and plastics industries, CCM has a uniform particle size, which can make the product texture uniform and improve physical properties; it has good stability and can improve the weather resistance and service life of the product. In flue gas desulfurization operations, it has high reaction activity and high desulfurization efficiency; it has moderate alkalinity, can effectively neutralize sulfur dioxide and is not easy to cause equipment corrosion; it has a low cost, which can reduce the desulfurization cost of enterprises.

| Specification(%) | ||||||

| Brand | MgO min. | LOI max | SiO2 max. | CaO max. | Fe2O3 max. | Size |

| CCM95 | 95 | 3 | 1 | 1.50. | 0.74 |

60- 200mesh 85%min. Passing through |

| CCM94 | 94 | 3.00-5.00 | 2 | 2 | 0.9 | |

| CCM93 | 93 | 3.00-5.00 | 3 | 2 | 0.9 | |

| CCM92 | 92 | 3 | 3 | 2 | 1 | |

| CCM90 refractory | 90 | 2.00-4.00 | 4 | 2.5 | 1.2 | |

| CCM90 abrasive | 89 | 6 | 3.5 | 4 | 2 | |

| CCM87 | 87 | 5 | 8 | 4 | 1.5 | |

| CCM85 abrasive | 84 | 8 | 10 | 3 | 2 | |