OKG is refractory raw materials factory for European refractory industry, high-density BFA grains for refractories is used as the lining material of tilting furnace. It can be used with fused alumina bricks, castables, etc. to manufacture refractory components such as furnace lining and launder, reduce the loss of refractory materials, and improve production efficiency. OKG specializes in providing alumina-based refractory raw materials for dynamic furnace linings at low prices and fast delivery.You can rest assured to buy Brown Fused Alumina for Tilting Furnace from us.

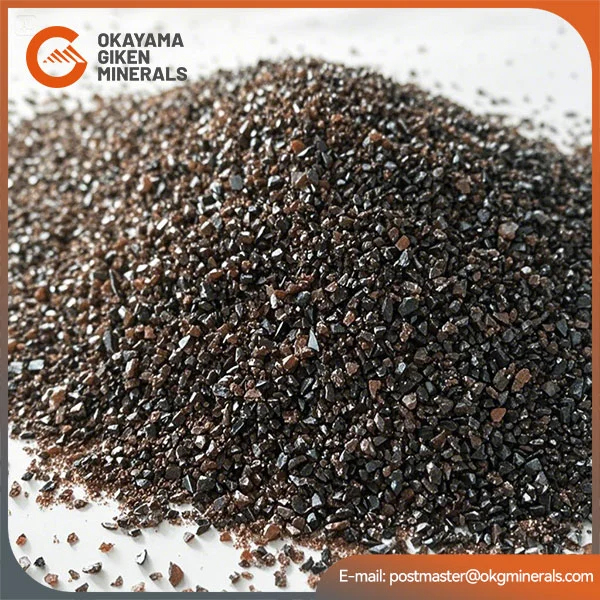

Brown Fused Alumina (BFA) for tilting furnace linings must offer outstanding slag resistance, abrasion resistance, and thermal stability to withstand the dynamic operating conditions of these furnaces. Compared with stationary furnace linings, high-density BFA grains for refractories are subject to frequent movement, metal-slag contact, and rapid temperature changes, making tough, high-density BFA essential for performance.

1. Furnace body can tilt for melting and pouring

2. Exposed to rapid temperature changes and severe thermal shock

3. Commonly used in non-ferrous metal melting and aluminum recycling

1. Focus on thermal shock resistance and slag corrosion resistance

2. Often blended with silicon carbide. spinel. or AZS for enhanced performance

3. Widely used in castables. gunning mixes. and plastics

4. Low iron content BFA is preferred to prevent metal contamination

5. As part of the functional layer. BFA improves localized lining durability

1. Brown corundum 3-5 mm /1-3 mm grit for tilting furnaces.

2. Brown corundum -200 / -325 mesh fine powder for tilting furnaces.

Due to their different roles in refractory castables and gunning mixes, coarse grit requires higher purity and bulk density, while fine powder may contain slightly more impurities to enhance sintering properties. This makes brown corundum (BFA) an ideal choice for tilting furnace linings, especially in non-ferrous metal smelting, where thermal shock resistance and slag erosion resistance are critical.

|

size At Buyers Option |

Specification(%) | |||||

| Al2O3 | TiO2 | SiO2 | Fe2O3 | CaO | ||

| grain size |

Dumping furnace |

≥95.0 | ≤3.5 | ≤1.0 | ≤0.2 | ≤0.4 |

| powder size | ≥95.0 | ≤3.5 | ≤1.0 | ≤0.2 | ≤0.4 | |

*We offer various packaging options for bulk refractory materials: 25kg bags with pallets, 1MT jumbo bags, and bulk-in-container loadings.

All packaging can be customized with waterproof liners, fumigated pallets, and private labels to meet your logistics and storage needs.