OKAYAMA GIKEN (Mining) Co., LTD.,is refractory raw materials expoter to Europe,China Brown Fused Alumina for Stationary Furnace holds a crucial position in the refractory industry. BFA refractory raw material for fixed furnace linings is known for high hardness and outstanding heat resistance, it serves as a vital raw material for fabricating refractory products.OKG specializes in providing low impurity brown fused alumina for high-temperature applications at competitive prices and fast delivery.

Brown Fused Alumina is a high thermal stability fused alumina, Brown Fused Alumina (BFA) for stationary furnaces is specially selected for its high thermal shock resistance, excellent mechanical strength, and chemical stability under high temperatures. These properties make it ideal for use in monolithic refractories, precast shapes, and furnace lining materials where consistent performance and long service life are critical. In Europe, South America, and Southeast Asia, this material is extensively used to manufacture refractory bricks and castables for blast furnaces and converters in the metallurgical sector, as well as for cement kilns and glass furnaces in the building materials industry.

1. Stable structure. continuous high-temperature operation

2. Even thermal load

3. Commonly used in ladle preheating furnaces. trolley kilns. and heat treatment furnaces

1. Mainly used in wear-resistant linings and working layers

2. Emphasis on erosion resistance and thermal stability

3. Typically combined with mullite or high alumina aggregates for bricks or precast shapes

4. Requires uniform particle size and low apparent porosity for longer service life

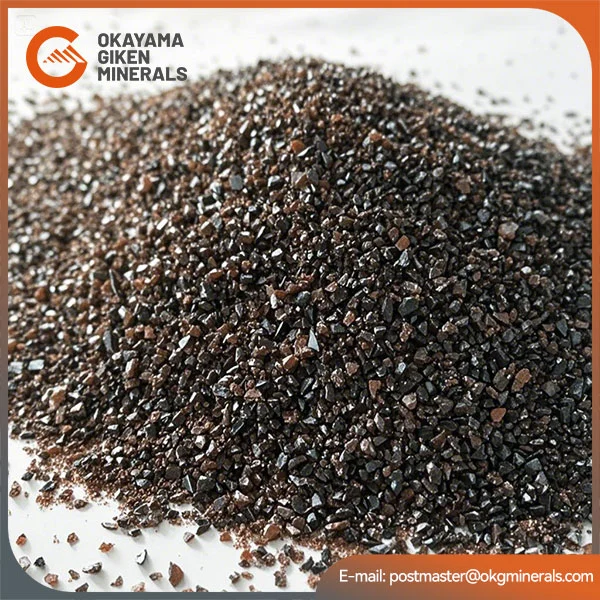

1. BFA 1-3mm. 0. 5-1mm grits for Stationary Furnace. mainly used as aggregate. providing mechanical strength. structural support. and wear resistance.

2. BFA -200 mesh. -325 mesh fine powder for Stationary Furnace. as a matrix. it fills pores. enhances density. and affects the bonding system (especially in low-cement or cement-free castables.

| size At Buyers Option | Specification(%) | |||||

| Al203 | TiO2 | SiO2 | Fe203 | Cao | ||

| grain size | fixed furnace | ≥95.0 | ≤3.5 | ≤1.5 | ≤0.2 | ≤0.4 |

| powder size | ≥94.5 | ≤3.5 | ≤1.5 | ≤0.2 | ≤0.4 | |

*We offer various packaging options for bulk refractory materials: 25kg bags with pallets, 1MT jumbo bags, and bulk-in-container loadings.

All packaging can be customized with waterproof liners, fumigated pallets, and private labels to meet your logistics and storage needs.